Gold ore crushing plant australia YouTube

#0183;#32;gold ore crushing plant process. Posted at:December 29, 2012[ 1922 Ratings] Gold ore processing plant, Gold ore mining and crushing process small gold plant for sale australia,small gold

WhatsApp)

WhatsApp)

#0183;#32;gold ore crushing plant process. Posted at:December 29, 2012[ 1922 Ratings] Gold ore processing plant, Gold ore mining and crushing process small gold plant for sale australia,small gold

Gold CIL (Carbon in Leach) Process is an efficient design of extracting and recovering gold from its ore. By cyaniding and carbon leaching crushed gold ore slurry simultaneously, CIL process lower the gold mining operation cost and increase gold recovery rate to a degree of 99%. View details.

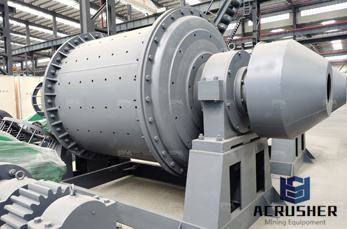

CIL gold processing plant mainly consists of following steps: 1 The ore is first reduced in size (typically 90% passing 200mesh ) to ensure that all nonrefractory gold is readily accessible for cyanide leaching, There are several variations of comminution circuits

The gold concentrator is designed as a conventional carbon in leach (CIL) arrangement. Underground ore is crushed to nominally minus 9 mm in a three stage hard rock crushing plant and then slurried and milled to nominally minus mm (75 m) in a single stage 3

#0183;#32;Process IQ is a Perthbased METS company with expertise in metallurgy and process engineering, helping mines improve throughput recovery and efficiency. +61 (0) 8 9240 4357 info HOME

Cil gold ore process plant australia. Australia bauxite ore crushing process,australias uranium,blackstone minerals ltd and mining in vietnam,cil gold ore process plant australia,colluasi copper mine,copper concentrate suppliers, all quality copper,copper statistics and information,copper, nickel, lead, and zinc mining global market,cost models of theoretical mining operations

This plant processes 4 million tons of ore per year with an average gold content of ounces of gold per ton of ore. Approximately 85% of the gold is recovered in the plant. From the ball and/or autogenous mill, slurry is pumped to the CIL leach tanks where lime adjusts the pH, if necessary, and it is agitated for the desired period of time.

The plant is a conventional CIL (Carbon In Leach) plant with a capacity to process about 340,000 tonnes per year of Charters Towers gold bearing ore. There is also a substantial gravity gold recovery circuit planned to be installed within the overall plant design to recover the coarse gold particles.

One of important process to in gold processing plant at PT Antam (Persero) Tbk. Pongkor Gold Mining Business Unit is CIL (Carbon In Leach) Process which cyanidation process occur. Pongkor has epithermal low sulfide and clay ore which have its own difficulty to process to get high gold

Gold ore . Prominer maintains a team of senior gold processing engineers with expertise and global experience. These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc., to achieve the processing plant of optimal and costefficient process designs.

The gold CIL process is mainly used in the oxide ore which has low grade of silver, its more economize and has more benefit . Process introduction CIL process is mainly include : decontaminate, concentrate before leaching, leaching and adsorption, desorption and electrowinning, hydrometallurgy, regeneration of activated carbon tailings filting, waste water treatement and so on .

#0183;#32;Fourth reasons why you should check out our new Mobile Gold CIL Plant: flexibility, versatility, reliability, and security. https:

Gold CIP Production Line. Process Introduction. CIP (Carbon in pulp) process is a high efficient method to leaching and recovering gold from gold ore, The most different from CIL process is in CIP process, gold leaching and adsorption are separated, first leaching, and then adsorption. Now it is being replacing by CIL process progressively.

Gold CIL (Carbon in Leach) Process is an efficient design of extracting and recovering gold from its ore. By cyaniding and carbon leaching crushed gold ore slurry simultaneously, CIL process lower the gold mining operation cost and increase gold recovery rate to a degree of 99%.

Gold ore CarbonInLeaching (CIL) processing technology. SBM work together with the famous laboratory in China to design and deliver the gold leaching plant. It help the mine factory to extract a major part of the residual gold contained in gold ore or some tailings.

#0183;#32;Our Commitment through COVID19. Following the recent outbreak of COVID19 and its subsequent elevation in status by the World Health Organisation, Process IQ has undertaken a proactive review of any health risks this may pose to our employees, clients, suppliers and our overall ability to serve our stakeholders in the mining and METS community.

Synergen Met, Australia, are continuing to progress their onsite cyanide production process towards full scale commercial applicationfollowing the successful operation of a 60 t/a pilot plant at an operating gold mine in Australia (4). They are targeting a modular design rated at 450750 t/y, with additional modules to be added for larger output.

WhatsApp)

WhatsApp)