Making a Ball Mill YouTube

#0183;#32;The milling of the materials is a very useful procedure in various domains in life as well as in the constructive domain. Click HERE to subscribe to Make it...

WhatsApp)

WhatsApp)

#0183;#32;The milling of the materials is a very useful procedure in various domains in life as well as in the constructive domain. Click HERE to subscribe to Make it...

Metallurgical ContentBall Mill Capacity VS Rod Mill CapacityWorking Principle amp; OperationRod Mill Capacity TableBall VS Rod Mill ConversionTypes of Mill DischargeBall Mill Trunnion and Mill Grate DischargePeripheral Grinding Mill DischargeLoad Capacity of Trunnion BearingsBall Mill amp; Rod Mill LinersGrinding Mill GearsGrinding Mill DrivesBall Mill Grinding CircuitBall Mill SpecificationsAll

Double Roll Crushers are useful for intermediate size reduction of hard to medium hard materials, The High Energy Planetary Ball Mill Pulverisette 5 PREMIUM with 2 working stations is the ideal mill for fast, wet or dry, grinding of larger sample quantities down to the nanometer range,

MIKRONS Triple / Three roll mill is a machine tool that uses the shear force created by three horizontally positioned rolls rotating at opposite directions and different speeds relative to each other to mix, refine, disperse, or homogenize viscous materials fed into it. We have over 23 successful years manufacturing three roll mills which have been selling worldwide.

DECO offers bulk lab roll ball mill for sale with cheap price. We''re known as one of the most professional lab roll ball mill manufacturers and suppliers in China, with the business principle of ''Customer is Superior, Quality is in the First Position Forever''.

MIKRONS is an Original Equipment Manufacturer of machineries such as Attritor, Agitator, Ball mill, Bead mill, Basket mill, High speed disperser, Jar mill, Mixer

Double pair mills for a consistent grind If your ideal micron size is 700 or greater then the RMS double pair mill is for you! The double pair mill will process all different kinds of materials and will consistently grind at your desired particle size.

Double Roll Crusher Double roll crusher applies to cement, chemical industry, electric industry, metallurgy, construction, refractory material etc. Double roll crusher is usually used in middle and fine crushing stage to crush medium hardness materials including limestone, coke, coal, gravel, gypsum, ores, mine refuse, furnace slag, steel slag etc.

double roll mining mill 750 tph. Triple roll crushers triple roll crushers are ideal for producers who want to accomplish two stages of reduction in one pass they can be used in coal, salt, coke, glass, and trona operations, among others triple roll crushers combine a single roll crusher with a double roll crusher to form a crusher that is capable of achieving a reduction ratio in the primary

the most popular double roll ball mill_Lab Roll Ball MillOverview Lab roll mill is a kind of equipment used for ultrafine grinding and mixing for laboratory and small batch production. The machine is preferred equipment for scienti

Roller mills are mills that use cylindrical rollers, either in opposing pairs or against flat plates, to crush or grind various materials, such as grain, ore, gravel, plastic, and grain mills are an alternative to traditional millstone arrangements in mills for rock complement other types of mills, such as ball mills and hammermills, in such industries as the

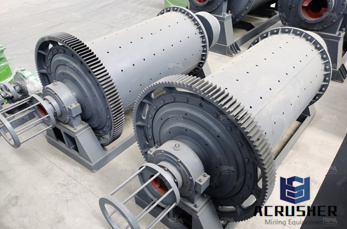

Ball Mills Steel Ball Mills amp; Lined Ball Mills. Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800s. The basic construction of a ball mill is a cylindrical container with journals at its axis.

Ball Mill consists of cylindrical shell rotating on a horizontal axis mounted on a sturdy Mild Steel Frame. The Ball Mill Shell is designed to withstand the rotational load of the mill charged with the grinding medium and the material to be processed.

A three roll mill or triple roll mill is a machine that uses shear force created by three horizontally positioned rolls rotating in opposite directions and different speeds relative to each other, in order to mix, refine, disperse, or homogenize viscous materials fed into it.. The threeroll mill has proven to be the most successful of the range of roll mills which saw extensive development in

Our Two Roll Mills are designed with many user friendly features like durability, compactness, ergonomic features, ease of mobility, user friendly operation amp; maintenance

Ball mills tumble iron or steel balls with the ore. The balls are initially 510 cm diameter but gradually wear away as grinding of the ore proceeds. The feed to ball mills (dry basis) is typically 75 vol.% ore and 25% steel. The ball mill is operated in closed circuit with a particlesize measurement device and sizecontrol cyclones.

Double Roller Crusher Introduction. Double roll crusher is reliable in operation, simple in maintenance, low in running cost, and discharge size can be adjusted. It is widely used in the processing of brittle materials and tough materials in cement, metallurgy, chemical

WhatsApp)

WhatsApp)