industrial process of calcite

CALCITE Industrial Applications :: Miracle Minerals

WhatsApp)

WhatsApp)

CALCITE Industrial Applications :: Miracle Minerals

Processing and production of industrial fillers based on calcium carbonate . UK calcium carbonates are a nationally significant source of raw materials. Commercial calcium carbonate grades, in the form of powders, granules and slurries, are produced in 2 ways: through the extraction and processing of natural ores or synthetically through chemical precipitation. Ground calcium carbonate

CALCITE Industrial Applications. Used in pollution control, neutralizing chemicals for acid wash, and source of calcium salt. An application of this is also in bulk industries like cement, steel and others. Used in rubber industry as a bulk filler, in many rubber products.

Calcite powder Manufacture, Supplier amp; Exporter for Paper. Since calcite increases the whiteness of paper, naturally grinded calcite is preferred where costs of making pulp are high since it diminishes the requirement of additional whitening pigments. This also makes the process more ecofriendly.

The thermal decomposition process of calcite particles ( mm average diameter), made up of porous agglomerates of very small CaCO 3 microcrystals, was studied in the K temperature range. The experiments were carried out under isothermal conditions in air atmosphere, in CO 2 atmosphere, as well as in a gas stream comprising different concentrations of air and CO 2.

Its chemical formula is CaCO3. Calcite is widely used in industrial processes. Paint industry, paper industry, plastics, glass production, building materials, chemicals, food and ceramic industries are some of them. Calcite, calcium carbonate conveying, storage, loading and feeding systems are widely used in

mining process of calcite_calcite mining process miningbmw quarry 14213 htmlCalcite Wikipedia, the free encyclopedia Calcite is a Impact crusher, jaw crusher mining equipments, sand making machines and industrial grinding mills, offering expressway, rail way and water conservancy projects the . Get Price . Calcite Wikipedia. Calcite is a carbonate mineral and the most stable polymorph of

As an industrial mineral it is an ideal raw material because of the diversity of grades it can produce. No one calcium carbonate is exactly like another. Whichever property is needed a high grade product is there to meet the demand. With its special white qualities as a filler and coating pigment, calcium carbonate is the most widely used mineral in the Paper, Plastics, Paints and Coatings

So I cubic foot (about 100lbs) of Calcite will treat about 96,800,000 mg of carbon dioxide. If water has 20 mg/l of carbon dioxide then 1 cubic foot will treat: (96,800,000 / 20) liters of water. Or 4,840,000 liters or 1,278,730 gallons of water. If the water usage is 10,000 gallons/day, then 1 cubic foot of Calcite

May 25, 2013#0183;#32;The calcium carbonate thermal decomposition process in calcite particles ( mm average diameter), made up of aggregates of microcrystals smaller than mm, was studied in the temperature range K.

Calcite is the primary ore of calcium. Calcite is indispensable in the construction industry, forming the base of cement. Many important chemicals are created from Calcite, as well as useful drugs. It is also crucial in the manufacture of fertilizers, metals, glass, rubber, and paint.

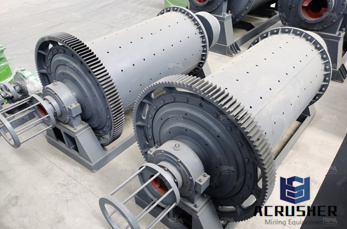

Industrial Process Of Calcite: production process of calcite minerals excellent mining crushing machinery products or production line design, as it is used for industrial purposes, manufacturing process of calcite powder . Read More; Quality control in sensorbased sorting for . Process Of Crushing Calcite hylandalechurchschool . Limestone Calcite Crushing

industrial process of calcite foundryalloysin A carbon dioxide scrubber is a device which absorbs carbon dioxide (CO 2)It is used to treat exhaust gases from industrial plants or from exhaled air in life support systems such as rebreathers or in spacecraft, submersible craft or airtight chambers Get a Price industrial used large capacity.

Manufacturing Process Of Calcite Powder. We are a professional mechanical equipment manufacturer, we provide original parts, service solutions, extensive training and extensive wear, crushing chambers and screening media solutions to reduce operating costs, improve product quality and maximum productivity. Email [email protected] Office Address. Hightech Zone, Zhengzhou, Henan, China.

The widely distributed calcite is also known as stalactite with the hardness within and specific gravity within Calcium carbonate is the main component so it can be used to produce heavy and light calcium powder. Calcite with different fineness is widely used in papermaking, medicine, chemistry and agriculture. Heavy calcium is closely related to people''s lives. In the past

Calcite, the most common form of natural calcium carbonate (CaCO 3), a widely distributed mineral known for the beautiful development and great variety of its crystals. It is polymorphous (same chemical formula but different crystal structure) with the minerals aragonite and vaterite and with several forms that apparently exist only under rather extreme experimental conditions.

Calcite is number 3 on the Mohs hardness scale; thus, it can be scratched readily by a knife blade or geologic pick. It has a specific gravity of Three perfect cleavages give calcite its sixsided polyhedrons with diamondshaped faces; the angles defining the faces are 78#176; and 102#176;. The three important crystal habits (distinctive shapes of the mineral) of calcite are: (1) prismatic

Calcite is most commonly occurring industrial mineral in the earths crust. Limestone, which is the one of the most abundant minerals found, comprises around 95% calcite. Calcite is thus categorized under the group of carbonates which are isomorphs of one another. The most common forms of calcite found in nature are chalk, marble and limestone. These forms are produced by the sedimentation

Mineral Process Of Calcite. Calcite mineral ore crushing process. Calcite ore mining crusher for sale Mineral Stone Crusher Although the part of the process does not belong to the process section, but it can guarantee calcite . Flotation Separation Of Fluorite From Calcite Using. Jul 01, The mineral samples of fluorite and calcite were ground to 2 m. g of the mineral sample was

WhatsApp)

WhatsApp)