Manufacturing Process of Clay Bricks YouTube

#0183;#32;watch this video To know the information of clay brick A brick is building material used to make walls, pavements and other elements in masonry construction....

WhatsApp)

WhatsApp)

#0183;#32;watch this video To know the information of clay brick A brick is building material used to make walls, pavements and other elements in masonry construction....

offers 2,175 automatic clay brick manufacturing plant products. A wide variety of automatic clay brick manufacturing plant options are available to you, such as local service location, key selling points, and brick raw material.

#0183;#32;Visit the largest clay brick manufacturer in North America. This is a visit to the plant to see how we make the highest quality brick

Canterbury Clay Bricks manufacturing plant is located close to its clay supplies within the surronding hills of Darfield. A number of recycled products are used in the manufacture of the bricks including reconstituted brick and recycled glass. The kilns at the plant run on up to 95% of reclaimed fuels and oil further reducing any impact

Kuzminetsky brick plant is a modern manufacturing facility for production of ceramic blocks. Total area of the buildings is about 16,000 square meters, which are located on a land plot of 3 hectares, owned by the of the plant is highly advantageous from the perspective of proximity to the transport infrastructure (railway, roads, river port); the distance to Kyiv is about 80

Design a clay brick manufacturing business plan systematically through keeping in view the manufacturing steps and business solutions for strategic marketing and sell. Combine marketing, operations, staffing setup and financial plans together for genuine business strategy to

According to the plan, the manufacturing plant will have a production capacity of 90,000 pieces of clay roof tiles or 100,000 pieces of bricks per day. The enterprise intends to establish and run

Manufacturing of Brick . Abstract: This . Technical Note. presents fundamental procedures for the manufacture of clay brick. The types of clay used, the three principal processes for forming brick and the various phases of manufacturing, from mining through storage, are discussed.

Manufacturing of fired bricks at high temperature has certain limitations, such as high energy consumption, accounting up to 40% of the total cost of clay bricks production (Shakir and Mohammed

offers 3,631 clay brick manufacturing plant products. About 0% of these are Plastic Extruders, 0% are Cement Making Machinery, and 0% are Crusher. A wide variety of clay brick manufacturing plant options are available to you, such as warranty of core components, local service location, and key selling points.

It is yet another common method for moulding of bricks in mechanized brick manufacturing making plants. In this method, only a very small quantity of water is added to finely crushed and thoroughly cleaned clay. So that the resulting clay mix is not a

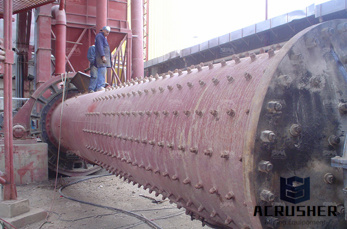

Manufacturer of Bricks Making Machines Clay Brick Manufacturing Plant, Handling Equipment For Freshly Extruded Brick, Hollow Hourdis and Clay Extruder With Wire Cutting Table offered by Suncabs Travels India Private Limited, Coimbatore, Tamil Nadu.

WhatsApp)

WhatsApp)