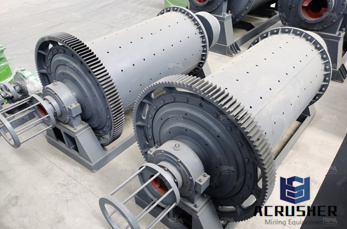

8 Working Stations Jar Mill Ball Mill For Material Grinding

Home Products Ball Mill Planetary Ball Mill 8 Working Stations Jar Mill Ball Mill For Material Grinding

WhatsApp)

WhatsApp)

Home Products Ball Mill Planetary Ball Mill 8 Working Stations Jar Mill Ball Mill For Material Grinding

An improved control strategy is proposed to control ball mill grinding circuits for energy saving and pollution reduction. A two layer optimizationbined by particle size optimization layer and energy optimization layer is developed, where the optimal particle size set point is calculated first, followed by the energy optimization step.

Grinding Mills: Ball Mill Rod Mill Design Parts. Con grinding medium is an improved type of ball grinding media which offers more surface area per unit of weight, and has found extensive use in the grinding of cement clinker. The advantage of Con medium is its ability to increase mill capacity because of its interlocking shape and

In 2010 fritsch redesigned its pulverisette 5 planetary ball mill for a range of sample grinding ideal for mixing and homogenizing emulsions and pastes in 2010 verder introduced the retsch grindomix gm 300 knife mill for the grinding and homogenizati,Improved station grinding ball mill.

quality spare parts and consumables like grinding media . Ball mills are predominantly used machines for grinding in the cement industry. Although ball mills have been used for more than one hundred years, the design is still being improved in order to reduce the grinding costs.

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (, via a hand crank), working animal (, horse mill), wind or water ().

CHAENG energyefficient ball mill equipment is new equipment to transform the basis of the traditional ball mill after, It changed the original mill structure, it is possible to reduce energy consumption by 30%, capacity increased by 1520%, it is widely used in cement silicate products, new building materials, refractory materials, fertilizer, metal ore and glass ceramics etc. production

grinding mill for coal fired power station . Modification And Change In Ball Mill. China Supplier of Methods of Modification And Change In Ball MillTrade show has always been a barometer of market development, it is learned, Methods of Modific. Mining Equipment For Ore Surface Processing.

grinding by means of ball mills, which are being applied at heat power stations for grinding the coal, at cement plants for grinding the clinker and at ceramic plants for grinding the clay. The developed system provides continuous monitoring of the grinding, ventilating and drying productivities and it optimizes

The use of small grinding media in regrind mills proved that finer grinding can be achieved at lower energy consumption. In ball mills, smaller grinding media versus 25 mm media generate a power saving from 10% to 44%. In vertical stirred mills, the power saving increases from 20% to 60%. More potential savings have been identified.

improved design of mining grinding ball mill in rwanda. Optimization of mill performance by using online ball and pulp measurements J o u r n a l P a p e r The Journal of The Southern African Institute of Mining and Metallurgy VOLUME 110 NONREFEREED PAPER MARCH 2010 135 Table I Influence of speed and liner design on load dynamics Mill speed Soft design Aggressive design...We are a

Although ball mills have been used for more than one hundred years, the design is still being improved in order to reduce the grinding costs. HOLTEC has undertaken Performance Optimisation of the cement grinding circuits by doing process diagnostic studies in many cement plants.

ball mill used for bhusawal thermal power station . Nov 17, Ball Mills In Coal Power Plant,Binq. coal ball and rice mill power plant Grinding Mill . used in power plant This page is provide professional used in power plant information for you, we have livechat to answer you coal ball.

critical speed of the mill. Ball mills are usually operated at 6080% of the critical speed for better attrition and impact effects. Change of supply frequency causes change in grinding. We can see a more load pick up as frequency rises and vice versa in ball mill.

In ball mills, smaller grinding media versus 25 mm media generate a power saving (70%) was tested in a pilot station by Companhia Vale de Rio Doce (CVRD), consisting of a small ball mill with discharge overflow running in closed circuit with one was improved by 16%. Most of laboratory testworks are using one or two sizes of media to

Download Citation | The improved system for automation and optimization of solid material grinding by means of ball mills | This work deals with the system for automated control and optimization

Ball mill and rod mill are suitable for different materials 1. Selection by material''s hardness Ball mill has a strong adaptation of material, and it is suitable for grinding hard materials, such as slag, iron ore, copper ore, etc. Rod mill is suitable for grinding brittle material, such as rare metals. 2. Selection by required particle size

WhatsApp)

WhatsApp)