slurry mills raw material

Rawmill Wikipedia

WhatsApp)

WhatsApp)

Rawmill Wikipedia

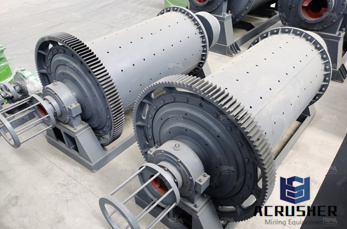

Slurry Flow Rate Through a Mill. Slurry Flow Rate Through a Mill. CEMENT MANUFACTURING A WET PROCESS WITH THE FLOW DIAGRAM. In the wet process, 1) The raw limestone from quarries is first crushed to small size fragments. The ball mill is a key piece of equipment for grinding crushed materials and it is widely used in production lines

The Raw material, which is used for manufacturing of cement, contains the following materials: CALCAREOUS ( chalk consists of limestone.) ARGILLACEOUS ( clay consists of

01/01/2020#0183;#32;The indestructible waste of mining and cutting activities of marble, marble slurry can be used as building material having good strength which is also costeffective. The objective of the work is to utilize mill scale and marble slurry to make strong, durable and thermally insulating brick or tiles. 2. Materials and methods

The raw materials are taken in a ball mill and them grinded with water for certain hours. The grinding media is usually alumina because it has good wear resistance and good density. This process is known as wet grinding. The raw material will be obtained in a slurry form at the end of the wet grinding process. The slurry is stored in a slip tank; The slurry is continuously rotated in order to prevent the setting of

30/08/2012#0183;#32;Kiln is a huge rotating furnace also called as the heart of cement making process. Here, raw material is heated up to 1450 C. This temperature begins a chemical reaction so called decarbonation. In this reaction material (like limestone) releases the carbon dioxide. High temperature of

01/01/2000#0183;#32;Wet milling by a multiring media mill was carried out for aqueous slurries of Mg(OH) 2 and TiO 2 powder mixtures in the concentration range from to 50 wt%. Rings used as grinding media were made of partially stabilized zirconia or polyoxymethylene.

Our used equipment range changes regularly and consists of umbilical slurry systems, farm trailers, slurry tankers, dribble bars amp; Doda pumps. Our sales team are available to answer any questions. To talk to us about any of our used farm machinery call our team on (+44) 028 3882 0862

Slurry mill. Especially for seeding as a preliminary stage of product crystallization proper, the use of a slurry suspension is now state of the art. BMA''s supply line of crystallization equipment also includes a slurry mill operating by the ball mill principle, using hardened steel pebbles. The use of seed crystals of a defined size and number to stimulate crystallization of sugar solutions is a decisive improvement over

The OKTM Mill skilfully comminutes raw material, cement and slag. It features a patented roller and table design and concrete mill stands instead of traditional, heavy steel structures. The OKTM Mills flexible design makes it possible to operate it with a number of rollers out of service while still reaching 60 to 70 percent of the normal operation output, minimising production losses.

15L Slurry Vacuum Mixer Machine For Raw Materials. SPECIFICATION. 1. characteristic: 1)vacuum degree :,maintaining over 12h. 2)sets of mixing roller, with material SUS304 stainless steel, the revolution speed can be adjusted . parameters: 1)voltage rating/power:220V/ 2)rotate speed:01400r/min; 3)effective volume:5L.

WhatsApp)

WhatsApp)