Coal Mill For Cement Plant

Coal Mill For Cement Plant. Indian Cement Review 2002 Quality Of The PTFE Membrane Can Determine The Production Rate In A Cement Plant Case Study 1 Exceptional 7 Years of Bag Service Life in Cement.

WhatsApp)

WhatsApp)

Coal Mill For Cement Plant. Indian Cement Review 2002 Quality Of The PTFE Membrane Can Determine The Production Rate In A Cement Plant Case Study 1 Exceptional 7 Years of Bag Service Life in Cement.

Best Bag For Coal Mill In Cement Plant. Best Bag For Coal Mill In Cement Plant; Dry cement process intensivfilter. In another mill, gypsum is added to form the end product cement. The pollutants released in this branch of industry is considerable. With IntensivFilter filtering installations, dust emissions can be lowered by more than 99%.

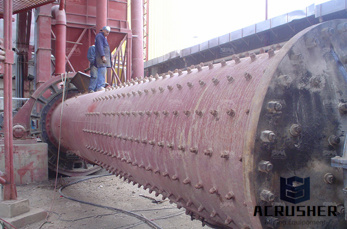

Ball mill is a traditional coal pulverizer machine, which has been widely used since it was invented. In the cement plant, the new dry process cement manufacturing requires the moisture content of coal powder to be % ~ %, while that of raw coal is % ~ %.

Filter Bag for Cement Plant During cement production process, there is a lot of dust and gas emissions outwardly, there are many different filter bags can be chosen for meet varied working condition. Capacity : 2000 pcs per day

a cement coal mill system, O 2 via leakage in the duct joints, from the mill chamber up to the dust collector / bag house. No matter how sophisticated and reliable O 2 concentration monitoring equipment can be, and often is when as far as coal mill plants are concerned, they do not go beyond general statements. Certainly, it is

Bag filters used for the coal mill rank as one of the highest fire and explosion hazards in cement plants, due to the small particle size of the crushed coal. 3) Electrostatic Precipitators Buildup of explosive mixtures like finely dispersed coal dust in air, or carbon monoxide in air can result in an explosion hazard in Electrostatic

According to the company a cement plant NSP kiln of supporting the preheater and coal mill system, it has happened so many times grinding head on fire, and cause coal mill bag dust collector fire accident, flat bag burned down all studied, coal mill bag dust collector the cause of the fire and the preventive measures.

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

VG: At best, coal mill safety is not well understood and, at worst, it is ignored. When it comes to coal mill systems, most cement plant operators just presume that the supplier of the equipment knows all of the standards and rules and is capable of making

Oct 07, 2019#0183;#32;For a coal mill dust collector, velocity should not exceed 240 fpm or m/s. Filter bag selection. Polyester, acrylic, and aramid filter bag fabric materials require a dust cake for fine particle filtration. This can lead to an increased risk of combustion.

Mill explosions will only occur when three conditions exist: sufficient oxygen (12 per cent O 2inair), the presence of an ignition source (gt;30mJ) and airsuspended coal dust in a bandwidth of 502000g/m 3. Safe operation of coal mills seeks to avoid these conditions and many monitoring systems exist to provide fire and explosion protection.

InputOutput for a typical Cement plant 4 Normalisation Factor considered 5 Equivalent major grade of cement production 5 Calculation for Gate to Gate Specific Energy Consumption (SEC) 6 Methodology (Summary) 7 5. Target Setting in Cement Plants 7 Grouping of Cement plants 7 Energy Consumption Range 8

To summarize the coal mill controls, they may be divided basically into two major categories:. 1. To control the quality of coal being sent to the burners located on the furnace walls. The word quality here means the temperature and fineness of the PF. The set temperature values are dependent on the percentage of volatile matter that exists in the main fuel.

Coal Mill: Mill Bag filter jamming. Kiln Fluctuating Free lime in clinker. Cement Mill: Mill tripping at higher cement temperature. Cement Silo: Coating in cement Silo #169;CEMENTINDUSNEED CEMENT PLANT TALKPROCESSMARCH 2019

O2 + CO Percent at bag filter outlet and in fine coal bins. Bag filter hopper and fine coal bin temperature (0 C). Elements of Coal Grinding System: Mill Feeding: Consists of following activities Coal Crusher: Generally, require when ball mill is used for grinding and raw coal size is on higher side(gt;25mm).

According to the company a cement plant NSP kiln of supporting the preheater and coal mill system, it has happened so many times grinding head on fire, and cause coal mill bag dust collector fire accident, flat bag burned down all studied, coal mill bag dust collector the cause of

Jan 19, 2014#0183;#32;The raw is then fed to the coal mill VRM via weigh feeder, drag chain and screw conveyer. Important Parameters Of Coal: Residue on 90 micron=1820% Residue on 212micron=% Moisture =% Volatile Matter =2030% Ash content =2832% Coal Mill:Coal Mill is an important integral part of cement plant.

Their applications range from small workplaces to large industrial facilities such as coalfired power plants and cement plants. Compared to other types of air pollution control () equipment, baghouses are incredibly versatile and can be engineered for almost any dust producing application by varying size and bag types.

Nitrogen inertisation System / Nitrogen inertisation system . Gaztron engineering private limited are Designing and Manufacturing of Nitrogen Inertization System (Inertisation systems) Coal Mill, Silos amp; Bag Filters in the Cement Industry, We undertake full project on Turn Key bases on EPC Bases, Gaztron has Experience for EPC services of Nitrogen inertisation / inertisation system as per

World Cement. lm28d coal mill and a lm 53 cs cement millhe coal mill will grind 40 tph at a fineness of 5 r 90 m and has a 700 kw gearboxhe lm 53 cs mill has a capacity of 200 tph cem 1 with a fineness of 3500 blaine and a 4700 kw gearboxhe commissioning of the new mills in the batiske ske cimento sanayii tas cement plant is planned in.

b) bag filter for coal grinding system installed. 1998: vertical roller mill for cement grinding installed. additional esp installed in kiln/vrm circuit: 1999: a) cis/cfg cooler installed b) low pressure cyclone installed c) latest technology lv tech classifer installed in raw mill d) kiln capacity increased to 2800 tpd. 2001

Coal Mills for Cement Plants Coal grinding mills LOESCHE coal grinding mills are distinguished by characteristics that improve efficiency, safety and environmental protection, from the standard version to topoftherange installations.

Specializing in the sale of second hand cement plant equipment, and complete used cement plants. In addition to used and new surplus Cement Plant Equipment (rotary kilns, ball mills, vertical roller mills), NMI deals in many other types of machinery, including used equipment for Bulk Material Handling, Crushing, Grinding, Industrial Mineral Processing, and Power Plants

Best Bag For Coal Mill In Cement Plant. FOB Reference Price:Get Latest Price Coal mill in cement plant sites coal mill in cement plant sites coal mill in cement plant search in title displaying 1 20 out of 118 websites flowers online send flowers plants gifts same day flower delivery add to pare order fresh flowers online with sa.

WhatsApp)

WhatsApp)