Grinding Wheels | McMasterCarr

Choose from our selection of grinding wheels, including over 3,500 products in a wide range of styles and sizes. In stock and ready to ship.

WhatsApp)

WhatsApp)

Choose from our selection of grinding wheels, including over 3,500 products in a wide range of styles and sizes. In stock and ready to ship.

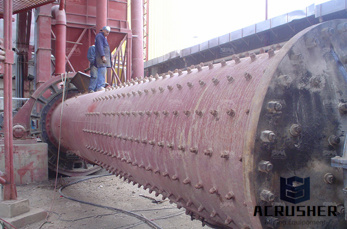

Grid type ball mill is mainly consists of cylinder, feeder, discharging device, rotating assembly, bearing and lubrication system. The grid plate has the function of isolation, which can significantly enhance the impact force of the steel ball. Therefore, the material will be fully ground with intense impact. 1.

Grate discharge Dry Grate discharge Wet Overflow discharge Wet Figure Effect of mill filling on power draft for ball mills. The data is taken from Rexnord Process Machinery Reference Manual, Rexnord Process Machinery Division, Milwaukee, 1976 The effect of varying mill speed on the power drawn by the mill is shown graphically in Figure

In order to avoid over crushing, the client selected Xinhai wet type grid ball mill in grinding process. The grinding medium are steel ball and ore itself, the grinding efficiency is high, it also adopts the hydrostatic and hydrodynamic bearings, which ensures the smooth operation and easy to grinding.

Great production capacity includes overflow energysaving rod mill and grid type energysaving rod mill. the medium is steel rod . Choose the ball mill type according to beneficiation demands Equipment installation, system monitoring Design optimization.

The grate type industrial wet grindersis devided into short cylindrical ball mill which is suitable for coarse grinding, and long cylindrical ball mill which is suitable for fine grinding. The overflow type industrial wet grindersis always used in the secondary grinding, while the grate type is always used in the first grinding, forming the closedcircuit with the spiral classifier.

#0183;#32;Description. Screens and bar grates are the key factor in determining the consistency of the finished particle size. Positioned over the discharge opening, the screen or bar grate ensures that no material evacuates the grinding chamber until it meets the target finished particle size.

In the process of Tungsten concentrates original production, the owner adopted grid type ball mill method in two stage grinding process to achieve great capacity. After a period, the client found the production didnt reach the standard, and the equipment had a serious consumption, so the client adopted Xinhai wet overflow ball mill.

China Grinder Mill manufacturers Select 2020 high quality Grinder Mill products in best price from certified Chinese Grinding Machine manufacturers, Grinding Equipment suppliers, wholesalers and factory on

Wet EnergySaving Grid Type Ball Mill. Discharge grid, less grinding, preventing the ball from discharging; High efficiency and energy saving, forced discharged, coarse grinding size, and great production capacity. Case More. Wet EnergySaving Overflow Ball Mill. Reverse spiral impeller, returns the steel ball and coarse ore to ball mill;

Metallurgical ContentOptimize Ball Mill Liner ReplacementLorain Shell LinersMill HEAD LINERSMill LINER BOLTSEffect of Liner Design on Mill Performance There are many different designs and styles of ball mill liners. As with grinding balls local economics and ultimately operating costs determine the best design and material to use. The initial set of liners is rarely the final design selected

Wet EnergySaving Grid Type Ball Mill. Discharge grid, less grinding, preventing the ball from discharging. High efficiency and energy saving, forced discharged, coarse grinding size. Great

Energy Saving Ball mill [ Capacity ]: t/h [ Applicable Material ]: Ball mill is key equipment for grinding materials after crushing process. It is used to grind kinds of materials into fine powder 2075micrometer. Based on discharging type, It could be grate type,overflow type etc.

Wet Grid ball mill is mainly used for mixing and grinding materials in two types: dry grinding and wet grinding .It has advantages of fineness uniformity and power saving. The machine uses different types of liner to meet different customer needs. The grinding fineness of material can be

Metallurgical ContentTypes of Ball Mills Ball Mill GrindingExample of Plant Capacity GainsBall Mill SpecificationsCompare Type of Mill DischargeGrate Discharge Ball Mill CapacitiesGrate Discharge Ball Mill Arrangement amp; Dimensions Allow me to compare: Ball mills can be of the overflow or of the grate discharge type. Overflow discharge mills are used when a product with high specific surface is

D. Sumanth Kumar, Mesh, in Synthesis of Inorganic Nanomaterials, 2018. Ball Milling. A ball mill is a type of grinder used to grind and blend bulk material into QDs/nanosize using different sized working principle is simple; impact and attrition size reduction take place as the ball drops from near the top of a rotating hollow cylindrical shell.

WhatsApp)

WhatsApp)