rolling milling equipment process

rolling milling equipment process Milling Process, Defects, Equipment. Milling is the most common form of machining, a material removal p

WhatsApp)

WhatsApp)

rolling milling equipment process Milling Process, Defects, Equipment. Milling is the most common form of machining, a material removal p

Rolling milling equipment process rolling metalworking wikipedia overviewiron and steelother metalsmodern rollinghot and cold rollingprocesses in metalworking, rolling is a metal forming process in which metal stock is passed through one or more pairs of rolls to reduce the thickness and to make the thickness uniformhe concept is similar.

#0183;#32;Tags Rolling Mills; What Is A Rolling Mill? In metalworking, rolling is a metal forming process in which metal stock is passed through one or more pairs of rolls to reduce the thickness and to make the thickness uniform. The concept is similar to the rolling of dough. Rolling is classified according to the temperature of the metal rolled.

Alluminium Rolling Milling Process. Metallurgical processes and defects in steel products defects in steel products are defined as deviations in appearance, shape, dimension, macrostructure microstructure, andor chemical properties when compared with the specifications given in the technical standards or any other normative documents in.

Milling Lines has mechanism to scalp and remove the oxide surface of hot rolling or continuous casting process. Scalping oxide impurities contribute to the electrical conductivity when used in final product. Three in One Milling Technology In copper rolling process, it is indispensable to have a milling (scalping) section after casting upstream.

Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a work piece. This may be done varying direction on one or several axes, cutter head speed, and pressure. Milling covers a wide variety of different operations and machines, on scales from small individual parts to large, heavyduty gang milling operations.

Used Process Equipment Inventory. The Milling Process 11 It is beyond the scope of this book to describe the technical details of the milling process The following section Essentially thi is the separation of the bran andonly provides a brief summary of the general operations involved in the production of flour from wheat for readers who

Milling Process, Defects, Equipment. The milling process requires a milling machine, workpiece, fixture, and cutter The workpiece is a piece of preshaped material that is secured to the fixture, which itself is attached to a platform inside the milling machine. Online Chat Technology Milling

rolling milling equipment process; Machining Processes: Turning, Milling, and Drilling . A drill press or tapping machine is designed for drilling, but this process can also be performed using a milling machine. Chips are the bits of waste metal produced when machining a workpiece.

Milling is also commonly used as a secondary process to add or refine features on parts that were manufactured using a different process. Due to the high tolerances and surface finishes that milling can offer, it is ideal for adding precision features to a part whose basic shape has already been formed.

Tags Rolling Mills; What Is A Rolling Mill? In metalworking, rolling is a metal forming process in which metal stock is passed through one or more pairs of rolls to reduce the thickness and to make the thickness uniform. The concept is similar to the rolling of dough. Rolling is classified according to the temperature of the metal rolled.

#0183;#32;Rolling is the most important and widely used metal forming process because of its lower cost and higher productivity. The rolling process is best defined as the shaping of metals into semifinished or finished forms by passing between rollers rotating in opposite direction.

This process is vastly used in respect of any other rolling process. In this process, the metal is heated above the recrystallization the hot working process, the metal is changing its grain structure because of the heat, now there were a new set of strainfree grains in the metal and this process needs less amount of force which correspondingly reduces the quality of the

rolling milling machine process blast . rolling milling machine process. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of minerals. Contact Supplier. rolling milling machine process unicjean

rolling milling equipment process; rolling milling equipment process. In metalworking rolling is a metal forming process in which metal stock is passed through one or more pairs of rolls to reduce the thickness and to make the thickness uniform The concept is similar to . Get a Quote Send Message.

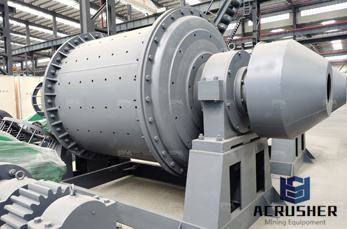

In a metal rolling process, rolls, stands, bearings, housing, motors, and other mechanical equipment are all a necessary part of the manufacturing operation. The place where all the equipment for metal rolling manufacture is set up is called a rolling mill. Rolling mills often vary in

rolling milling machine process. In the process of rolling, operators must focus the attention when starting the rolling machine however, for the assisting operator, he must timely and accurate command and cooperate with the main operator when there is the visual blind area for the rolling machine control to roll circular by pressing the upper roller repeatedly

Rolling is the most important and widely used metal forming process because of its lower cost and higher productivity. The rolling process is best defined as the shaping of metals into semifinished or finished forms by passing between rollers rotating in opposite direction.

The expansion process is expensive compared with other methods of feed manufacture in terms of equipment cost, heat used in generating steam and in ovendrying, and in loss of nutrients. It may be concluded that the value of extruded pelletsis best measured by practical feeding tests using data on feed conversion, cost of management, and acceptability by fish as deciding factors.

WhatsApp)

WhatsApp)