Attrition mill SPROUT WALDRON amp; COMPANY

The attrition mill as shown comprises a casing 4, which houses the operating disks for treating the material. Attached to 5 this casing is an inlet 42, to which the feed hopper 40 is attached. This inlet

WhatsApp)

WhatsApp)

The attrition mill as shown comprises a casing 4, which houses the operating disks for treating the material. Attached to 5 this casing is an inlet 42, to which the feed hopper 40 is attached. This inlet

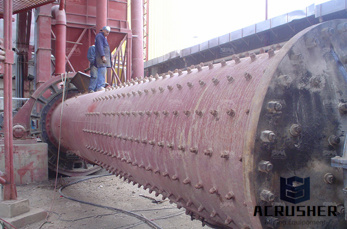

Attrition mill attrition mill Suppliers and Manufacturers. High Quality Forged Steel Balls and liners For Ball Mill Attrition Mill US Set 10 Sets Min Order 12 YRS Henan Engineering amp Technology Co Ltd 930 Contact Supplier Attrition Mill From. Attrition mill operating characteristics ScienceDirect

Attrition mill operating characteristics #183; The attrition mill is a device for mechanically reducing solid particle size by intense agitation of a slurry of material being milled and coarse milling media. For example, in 10 hours of milling,

The mill also includes the processes of attrition and impact, although these actions are limited if the material is easily reduced by cutting and the screen limiting discharge has large perforations. The mill consists of a rotating shaft with four attached parallel knives and

the function of attrition mill An Attrition Mill is used for reducing no bake bottom sand lumps to grain size of minus 20 mesh or green sand to small particles. Sand is dumped into the rear hopper section. The lumps rub on one another and produce fine grains which can convey up a steep incline.

mills tumbling attrition. Home; product; mills tumbling attrition; product list. K Series Mobile Crushing Plant; Mobile Vibrating Screen; Belt Conveyer; Sand Washing Machine; S5X Series Vibrating Screen; GF Series Vibrating Feeder; Ball Mill; Raymond Mill; MW Series Micro Powder Mill; T130X Superfine Grinding Mill;

The attrition mill as shown comprises a casing 4, which houses the operating disks for treating the material. Attached to 5 this casing is an inlet 42, to which the feed hopper 40 is attached. This inlet delivers into a centrally arranged opening 45 which in turn opens through a central opening 46 in a stationary part of the housing or head 47, which is rigidly secured to the casing 41.

Attrition Mill For Iron Ore Attrition Mill For Iron Ore; Mill (grinding) Wikipedia OverviewGrinding machinesGrinding lawsTypes of grinding millsSee alsoExternal links. In materials processing a grinder is a machine for producing fine particle size reduction through attrition and compressive forces at the grain size level.

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (, via a hand crank), working animal (, horse mill), wind or water ().

Attrition mills as such are of course well known in industry having had a wide variety of uses in many fields of industry for many years. The invention, however, provides a new and improved attrition hiill, in which the operating disks are provided with teeth particularly adapted to shredand deflberize tough fibrous materials such as the wet iibrous material of the process herein described.

Power characteristics of the attrition mill were essentially the same as those of a radial flow turbine mixer. Laminar flow became disrupted at NRe = 200, while turbulent flow was established at NRe gt;

Relationship among operational parameters, ore characteristics, and product shape properties in an industrial SAG mill. whereas the mills using attrition and abrasion mechanisms.

Jul 01, 1975#0183;#32;Power characteristics of the attrition mill were essentially the same as those of a radial flow turbine mixer. Laminar flow became disrupted at NRe = 200, while turbulent flow was

WhatsApp)

WhatsApp)