(PDF) Camber and wedge compensation in hot strip rolling

In this work, finite element simulations have been performed to model camber and lateral movement during hot rolling. To verify the results, experiments were made in MEFOS''s pilot plant mill.

WhatsApp)

WhatsApp)

In this work, finite element simulations have been performed to model camber and lateral movement during hot rolling. To verify the results, experiments were made in MEFOS''s pilot plant mill.

Is the flame roll out switch tripped in your furnace? In this video I explain what the flame roll out is, why it trips, and what you would need to do next. U...

#0183;#32;Another roll deflection model based on the beam theory for the evaluation of the roll deflection in plate rolling was used by Ohe et al. (1994), where they assumed the pressure distribution between the rolled plate and the work roll as well as between the backup roll and the work roll to be a polynomial of fourth degree.

should, when ordered from the mill, be noted no camber permitted. Otherwise, the mill may provide the members with a small amount of natural mill camber. g. Heat cambering should be performed only on lowcarbon steels. Application of heat to mediumand highcarbon steels increases the danger of embrittlement. ASTM A36, A572 Gr. 50,

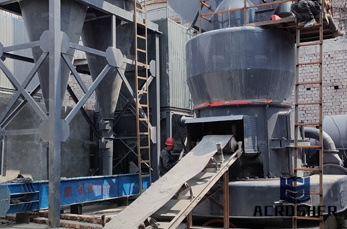

Different Properties of 2 Hi Rolling Mill and 4 Hi Rolling Mill . Many friends dont know what a 4 Hi Rolling Mill is. In fact, the 4 hi rolling mill is a combination of two working rolls and two supporting rolls. It is not only the drive mechanism for the backup roll, but also the work roll driven equipment.

cold rolling mill is of the type where shifting of both first intermediate and inner second intermediate rolls are possible. The rolls are numbered and defined as: 1. Work roll, diameter between 5075 mm. 2. First intermediate roll (tapered), diameter between 90105 mm. 3. Inner second intermediate roll (CVC roll), diameter between 177182 mm. 4.

7. #181; = Friction coefficient between work roll and sheet. 8. E = Youngs Modulus of work roll. 9. R = Radius of work roll. 10. MM = Mill modulus of mill. 11. T = Change in temperature at surface of work roll. 12. = Linear Thermal Coefficient of temperature of work roll. 13. L =

SPALLS IN WORK ROLLS..... 96 which are more or less very normal for rolling mills roll damage often occurs with consequences for the mill and the rolled product. Evidently the reasons of roll failure have to be discussed and determined

backup roll width: work roll dia: work roll width: mill screwdowns: hydraulic screwdowns previously setup for automatic gauge control. mill motor: 20 hp dc motor with :1 ratio. mill recoilers: 12 drums with 1 hp dc motors. mill gearbox: pinion stand. mill cooling: water cooled roll chocks. mill sled: roll

Work Roll Shift Mill. Primetals Technologies have been a pioneer in the field ever since we developed the world''s first Work Roll Shift Mill and have enhanced this technology based on our extensive experience in steel industry. Primetals Technologies utilizes the Work Roll Shifting at hot strip rolling field for different two purposes:

Aluminium rolling models: work roll camber. As many of you may know, we have developed a suite of process models for the aluminium rolling industry. These aluminium rolling models cover everything from ingot preheating to tension levelling.

The camber that must be ground into a roll is very specific to a particular work width, material, and force load. A roll must usually be manufactured for only one metal rolling process. In some industrial metal rolling processes, rolls are given temporary camber by applying forces through their bearings.

#0183;#32;Ground Cambers. 705 ] WESTERNPQAT 2030mm TEMPER MILL Porall~1 Backup Rolls Work Rotl Bending Jack Forquot; Fjw =90kN No It''quot;otrmal Camber ~ E '' h(l1VTl) P (kN/mm)tJ U ~ 1200 T~~ ~ W = 700mm ~O 6 ~ [email protected] I OL..d::~~~~~==:::::r:::=!:'':;:L;;~''~L:[email protected]~I o 200 600 800 1000 Distance from

#0183;#32;the roll gap, or the roll bite) between the work rolls. In this region the metal is plastically deformed, and there is slipping between the strip and the work roll surface. The necessary compression force is applied by hydraulic rams, or in many older mills by a screw arrangement driven by an electric motor [6]. Figure 1.

Get camber for 4 hi mill work roll Price. You can get the price of camber for 4 hi mill work roll and a Aamp;C representative will contact you within one business day. 4hi mill wark roll camber educationcare. Layout of a 4high rolling mill stand. rolling a convex strip camber of about %

Currently, work roll shifting mill is the most effective mill for strip shape control [12,13] because it improves the strip crown accuracy and edge phenomenon, as well as permitting schedule free

6Hi Mills. Waterbury Farrel 6Hi Mills provide improved flatness using a work roll bending mechanism and intermediate axial roll adjustment. These mills also provide improvements to the shape of rolled strip, increased reduction and greater rolling efficiency. Tandem Mill Improvements

WhatsApp)

WhatsApp)