Cement mill Wikipedia

Large balls are used at the inlet, to crush clinker nodules (which can be over 25 mm in diameter). Ball diameter here is in the range 6080 mm. In a twochamber mill, the media in the second chamber are

WhatsApp)

WhatsApp)

Large balls are used at the inlet, to crush clinker nodules (which can be over 25 mm in diameter). Ball diameter here is in the range 6080 mm. In a twochamber mill, the media in the second chamber are

Small production ball mill for ore grinding. This is a 3foot by 6foot continuous ball mill, and this machine will process one ton an hour at 65 mesh. You can actually process finer than that, down to about 200

All types of Ore Grinding Mills that consist essentially of rotating cylinders with flat or conical ends with balls, pebbles, or rods used as grinding media are included here. Ball Mills The term ball mill is generally used to refer to a cylindrical mill whose length is less than, equal to, but not much greater than its diameter.

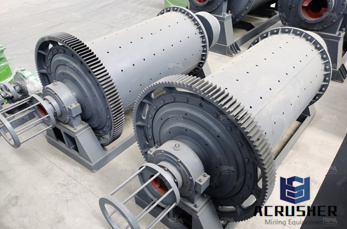

The ball mill for cement clinker grinding plant is an efficient tool for fine powder grinding. It is mainly used to grind the cement clinker and raw materials in cement plant and also can be applied in metallurgy, chemical, electric power and other industries to grind all kinds of ores. Cement clinker ball mill

The ball mill for cement clinker grinding plant is an efficient tool for fine powder grinding. It is mainly used to grind the cement clinker and raw materials in cement plant and also can be applied in metallurgy, chemical, electric power and other industries to grind all kinds of ores.

The ball mill for clinker is an efficient tool for fine powder grinding. It is mainly used to grind the clinker and raw materials in cement industry and also can be applied in metallurgy, chemical, electric power

The ball mill for clinker is an efficient tool for fine powder grinding. It is mainly used to grind the clinker and raw materials in cement industry and also can be applied in metallurgy, chemical, electric power and

The cement ball mill can perform dry process production and also wet process production, moreover it can do grinding and drying at the same time. CHAENG cement ball mill has features of small investment, high rate of return, simple process and easy operation. Advantages of CHAENG cement ball mill

Metallurgical ContentBall Mill Capacity VS Rod Mill CapacityWorking Principle amp; OperationRod Mill Capacity TableBall VS Rod Mill ConversionTypes of Mill DischargeBall Mill Trunnion and Mill Grate DischargePeripheral Grinding Mill DischargeLoad Capacity of Trunnion BearingsBall Mill amp; Rod Mill LinersGrinding Mill GearsGrinding Mill DrivesBall Mill Grinding CircuitBall Mill SpecificationsAll

Who We Are. Founded in 1987, ZJH is mainly focus on producing and supply the ore grinding equipment, mineral separation equipment and laboratory and pilot equipment for Mines and Mineral Processing Plants. Our aim is to work together with the Mining and Mineral Processing Industry for helping to carry on the production technical innovation, to reduce the operating cost,to improve the

Brief introduction of ball mill Ball mill machine is the key equipment for recrushing the materials after they are primarily crushed. It is widely used for the dry type or wet type grinding of all kinds of ores and

clinker grinding ball mill manufacturers in india. We provide high performing clinker grinding plant that is ideal for the efficient grinding of the clinker to produce cement our cement clinker grinding plant is comprised of precrusher, feed hopper, table feeders, material handling equipment, ball mill, blending and packing plant our cement clinker grinding

The ball mill is a key equipment to grind the crushed materials, and the ball mill is widely used in powdermaking production line including cement, silicate, newtype building material, refractory material,

Who We Are. Founded in 1987, ZJH is mainly focus on producing and supply the ore grinding equipment, mineral separation equipment and laboratory and pilot equipment for Mines and Mineral

Ball mill is widely used in metallurgy, mining, chemical, cement, construction, industrial and mining industries etc. Ball Mill Working Principle: The ball mill is a horizontal rotating device transmitted by

The ball mill for clinker is an efficient tool for fine powder grinding. It is mainly used to grind the clinker and raw materials in cement industry and also can be applied in metallurgy, chemical, electric power and other industries to grind all kinds of ores. Cement ball mill is not only suitable for overflow grinding, but also applicable for cyclic closeflow grinding together with powder collector.

China Iron amp; Gold Ore Cement Clinker Mining Wet Grinding Ball Mill, Find details about China Grinding Mill, Wet Grinding Mill from Iron amp; Gold Ore Cement Clinker Mining Wet Grinding Ball Mill Henan Sunstrike Machinery amp; Equipment Co., Ltd.

Cement mill grinding circuits using ball mills are used for grinding cement clinker into cement this energy is consumed for grinding clinker to cement powder .. chemical composition and fed to either a rotating ball mill or a. Burning is carried out in rotary kiln which rotating at 12 rpm at its longitudinal axis.

Small production ball mill for ore grinding. This is a 3foot by 6foot continuous ball mill, and this machine will process one ton an hour at 65 mesh. You can actually process finer than that, down to about 200 mesh, but the throughput goes down.

1,838 ball mill grinding clinker products are offered for sale by suppliers on, of which cement making machinery accounts for 7%, crusher accounts for 1%. A wide variety of ball mill grinding clinker options are available to you, There are 1,052 suppliers who sells ball mill grinding clinker on, mainly located in Asia.

Which is widely used in powdermaking production line including cement, silicate, newtype building material, refractory material, fertilizer, ore dressing of ferrous metal and nonferrous metal, glass ceramics, etc. Ball mill are generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns.

Because the steel ball in the ball mill is in contact with the ore, and the ball diameter is too large, the crushing force is also large, which leads to the fracture of the ore along the direction of penetration

WhatsApp)

WhatsApp)