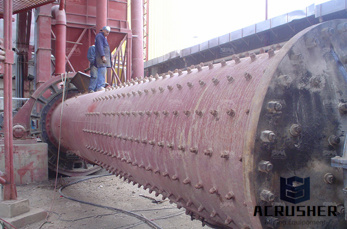

typical installation mill gold silver

GoldSilver Recovery from Mexican Ore When the millheading was crushed to 60mesh, the tailing from flotation assayed oz. gold, and 11 typical installation mill gold silver

WhatsApp)

WhatsApp)

GoldSilver Recovery from Mexican Ore When the millheading was crushed to 60mesh, the tailing from flotation assayed oz. gold, and 11 typical installation mill gold silver

How to Mill your Gold and Silver. by. Hank Chapman, Jr. From the Author of How to Smelt your Gold and Silver comes this new book written in 2015, How to Mill your Gold and Silver. 122 Pages tell you everything you need to know to Grind and Prepare your ore for processing whether it be gravity, Flotation, Cyanide or other methods.

#0183;#32;Milspecs such as 39029 are 50 microinches min but also allow localized finishing. We routinely process size 1622 gauge pc tail contacts and sockets with copper flash, nickel 50 min, sterling silver with about 1 micron of gold plating, the quality a college guy might give his steady date. Very good costume jewelry,

Most of the gold and silver produced comes from the processing of hard rock ores. There are a lot of different options for processing ores, and in the article below I''ll take a look at all of the best known possibilities for getting the gold and silver out of your ore and producing a clean gold and silver

typical installation mill goldsilver. InPlay from Briefing Yoo Finance. 14 hours ago The Company is taking the steps necessary to have its common stock quoted. so that the San Dimas mine and mill continue to operate uninterrupted. its goldsilver dor in Mexico and selling its gold

Vetran miner Mike Reynolds takes us through a tour of a gold processing mill that he has been working on for several years. He explains the process of taking...

Smaller denominations of gold plates: 1 gram, 5 grams, 10 grams, 20 grams, and 1 troy oz of gold. Larger denominations of gold plates: 50 grams, 100 grams, 250 grams, 500 grams, and 1 kg of gold. This 400 oz gold bar, at 2,000 per oz gold, is worth the 800,000 cash beside it. The gold bar is extremely heavy, weighing more than three full milk

typical installation mill gold silver; ball mills installation; installation of stone crusher machinery; gyratory crusher zenith manual installation; #187; Learn More Silver amp; Gold Inc. was a mining company Silver and copper are recovered by a flotation mill that produces a silver rich concentrate which is sold to third

Jun 02, 2010#183; Yea 100 mills is silver not gold but when u see pure gold that''s what u expect is pure gold not gold plated. It''s a rip off. Some people don''t have any money to lose or waste on trickery. I''m looking for an ounce of gold too I''ve been trying to find

Metallurgical ContentIntroduction to Gold and Silver LeachingGeneral Precious Metal Leaching TheoryHow Density of Solutions Affects LeachingWhat is the Effect of Aeration on Gold and Silver LeachingOxidizing Agents Decomposition of ReagentsHow Alkalinity (pH) Impacts Silver and Gold LeachingEffect Grinding and Particles Size Particle Size ClassificationGravity Gold Recovery in

A recent review (Kappes, 1998) concluded that for a quot;typicalquot; Nevadatype ore body with ore grade of grams gold/tonne ( oz/ton), the mill recovery would have to be 21% higher than the heap leach recovery to achieve the same return on investment and this is very seldom the case.

#0183;#32;The mine yielded more than 700,000 tons of gold and silver, according to the EPA. But the Gold King only operated until 1922, and was destined to

Typical Installation Mill Gold Silver. Operating costs of gold processing plantrecipitated gold and silver are refined in an induction furnace to produce dore bullion the crushing plant will operate independently of the mill in addition whereas the mill will be primarily run from local startstop stations the.

Over each consecutive term, gold and silver coin production decreased. In Trumps term so far, the value of public debt added to the system is almost 1,600 times higher than minted gold and silver coins combined.. During Obamas first term and Trumps term, debt saw a marked increase as the administrations provided fiscal stimulus in response to the global financial crisis and the COVID

Gravity Recovery and Leaching of Gold amp; Silver CIL Stripping amp; Refinery: This complete hydrometallurgical process plant is to recover silver and/or gold metals from oxide or very low sulphide ore deposits. Provided here are all major equipment for a plant arranged to recover dissolved precious metals using the CarboninLeach process. CIL with activated carbon is best suited for ores with no

refractory gold is readily accessible for cyanide leaching. There are several variations of comminution circuits used in the gold industry, such as: Multistage crushing and pebble and/or ball milling circuits, typical of older installations. The process design of gold leaching and

typical installation mill gold silver. Request a quotation * Your Name * Your Email * Country. Contact Tel * Application . For Construction (like concrete, highway, railway, brick, building, etc) For Mining ( like gold, copper, Iron ore beneficiation or nonmetal beneficiation, etc)

WhatsApp)

WhatsApp)