Homepage | Thermal Ceramics

Thermal Ceramics manufactures and installs a wide range of thermal insulation products such as Cerablanket, Kaowool, low biopersistent Superwool and Porextherm microporous products.

WhatsApp)

WhatsApp)

Thermal Ceramics manufactures and installs a wide range of thermal insulation products such as Cerablanket, Kaowool, low biopersistent Superwool and Porextherm microporous products.

Refractory Products Cement Kiln Refractory Thermal Ceramics. Refractory ceramic fiber as a kind of fiber lightweight refractory insulation materials has excellent properties of high heat resistance good heat stability low thermal conductivity low specific heat mechanical shock resistance and etc refractory ceramic fiber insulation refractory is widely used in industries of petrochemical steel

#0183;#32;This companys highstrength, low cement range of refractory monolithic lining materials is reportedly ideal for demanding, hightemperature applications in the metals, incineration, power generation, and minerals processing markets. The full range of products includes TriMor#174; Morflo#174; low cement castable and TriMor Higun#174; low cement gunning materials.

PicClick Insights Refractory Mortar Cement KBond Wet 3000F 2lbs Thermal Ceramics Firebrick Forge PicClick Exclusive. Popularity 32,152 views, views per day, 1,649 days on eBay. Super high amount of views. 388 sold, 159 available.

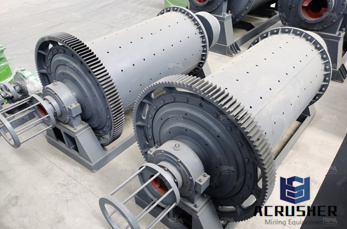

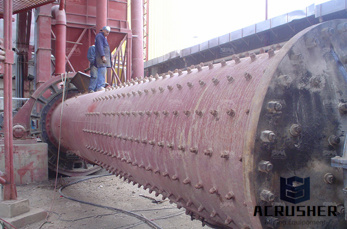

Thermal Ceramics manufactures a wide range of product solutions from traditional refractories to newer solutions in Cement applications like microporous. Cement is the worlds most important building product and a cement kiln is the worlds largest moving manufacturing machine. Cement kilns are enormous cylindrical ovens, some as long as

Understanding Refractory Failures in Fired Heaters Datasheets. TJMB4 IFB, K23 HS IFB, TJMB5 IFB, TJMC1 IFB, TJM26C IFB, TJMB6 IFB, TJMC2 IFB, JM26 HD IFB 15/05/2020; TJMB7 IFB, TJM28 IFB, TJM 30 IFB, TJM Ba90 IFB, Insalcor 15/05/2020; View all Related Datasheets Related Resources. Thermal Ceramics At a Glance 13/07/2020

Thermal Ceramics Kaowool#174; Refractory Pumpable, Application: For Hot or Cold Repair to Refractory Backup Insulation, Hot or Cold Repair of Boiler Insulation, Sidewalls and Penthouses, Brick Kiln Crown and Walls, Coke Oven Jambs and Seals, Color: Light Brown, Composition: 43 to 47% Alumina, 50 to 54% Silica, 2 to 4% Other, Container Type: Pail, Density: 23 to 28 kg/cum, Shelf Life: 6 to 12

Cement Murugappa Morgan manufactures high temperature fibre, refractory and Microporous insulation products and systems for thermal management in critical high temperature environments. In response to service conditions, stringent specifications for refractory kilns have developed.

Thermal Ceramics View Website. The Thermal Ceramics business of Morgan Advanced Materials makes advanced ceramic products and systems for thermal insulation in high temperature environments. We engineer products and systems petrochemicals, cement, ceramics and glass, and by manufacturers of equipment for aerospace, automotive,

The Thermal Ceramics business of Morgan Advanced Materials makes a range of fibre, kiln, and boiler operations. Fire Protection Fired Refractory Thermal Ceramics high temperature insulation refractories from 650#176;C to 1870#176;C (1200#176;F up to 3400#176;F)

Thermal Ceramics Superwool Fibre, Refractory Ceramic Fibre RCF amp; Microporous Insulation Manufacturer from Thane, Marashtra, India

Mortar cement mastics are offered to complement fibre and dense refractory products including pumpables, moldables, air setting cement and coatings. Company Description by Morgan Thermal Ceramics. Morgan Advanced Materials uses a wide range of specialist, highspecification materials that have extraordinary attributes and properties.

Thermal Ceramics manufactures a wide range of product solutions from traditional refractories to newer solutions in Cement applications like microporous. Cement is the worlds most important building product and a cement kiln is the worlds largest moving manufacturing machine. Cement kilns are enormous cylindrical ovens, some as long as

Refractory Lining is a layer of material which can resist high heat temperature in the kiln or furnace. The refractory lining can also resist thermal shocks, erosion, physical attack and chemical attack. If you are going to buy refractory lining in kilns, furnace or electric arc furnace, please contact RS Kiln Refractory Company! RS can provide you all the needed refractories materials for

The Thermal Ceramics business of Morgan Advanced Materials provides high temperature fibre, refractory and Microporous insulation products and systems for thermal management in critical high temperature environments. Our engineered solutions are used in the harsh environment of the cement kiln to help improve efficiency and reduce operating costs.

Kiln Cement: Kiln Mortar: Rated to 3000#176;F: Working Service Temp 3000#176;F: This is a wet product: Liquid and requires stirring: Model: KBond Wet Mortar: Country/Region of Manufacture: United States: Brand: Morgan Thermal Ceramics MORGAN ADVANCED MATERIALS: For use with Wood Stoves Firebrick: For use with Forge or Furnace Kiln Repair: For Repair

Refractory Products Cement Kiln Refractory Thermal Ceramics. Refractory ceramic fiber as a kind of fiber lightweight refractory insulation materials has excellent properties of high heat resistance good heat stability low thermal conductivity low specific heat mechanical shock resistance and etc refractory ceramic fiber insulation refractory is widely used in industries of petrochemical steel

This companys highstrength, low cement range of refractory monolithic lining materials is reportedly ideal for demanding, hightemperature applications in the metals, incineration, power generation, and minerals processing markets. The full range of products includes TriMor#174; Morflo#174; low cement castable and TriMor Higun#174; low cement gunning materials.

Morsil nitridebonded silicon carbide refractory shapes have high thermal conductivity, superior thermal shock and oxidation resistance. They also have higher hot strength compared to oxide bonded silicon carbide refractories. This makes them an idle choice as kiln furniture.

We offer Thermal Ceramics monolithic insulating materials in a wide range of engineered formulations for use as hot face or backing linings in challenging thermal environments. The range includes products that can be cast, gunned, rammed, poured, plastered, pumped and shotcreted.

WhatsApp)

WhatsApp)