Cold rolling | SMS group

SMS group offers various cold roll mill technologies for copper, steel and aluminum like tandem cold mill, 18 HS mill, reversing mill, skin pass mill, single stand cold mill

WhatsApp)

WhatsApp)

SMS group offers various cold roll mill technologies for copper, steel and aluminum like tandem cold mill, 18 HS mill, reversing mill, skin pass mill, single stand cold mill

Modernization of a Tandem Cold Rolling Mill at Arcelor Eisenh#252;ttenstadt Modernization at the stateoftheart As part of the modernization of a 4Stand Tandem Cold Rolling Mill of Arcelor Eisenh#252;ttenstadt , ABB replaced the drive and automation equipment as well as the process control computer for production management and presetting.

Cold rolling mill ArcelorMittal in Belgium. The tandem mills consists out of a series of rolling stands that thin the steel strips. One of our tandem mills works exclusively for the automotive industry, the other produces products for the remaining branches.

A typical five stand tandem cold rolling mill is illustrated in Figure 1. Figure 1: A typical five stand tandem cold rolling mill [Steel] The cold rolling mill DMS 20Hi YouTube. Jun 06, 2019#183; The cold rolling mill DMS 20Hi EcoMill with unique design is ready to roll strip down to 40 microns for highend applications at Shanghai STAL, China.

Tandem cold rolling mills can be basically split into two groups; sheet mills if they reduce hot band to sheet gauge or tin mills if they roll the same incoming material to tinplate stock. Key advantages of the tandem rolling process include cost reduction and good improvements in productivity especially when integrated with a continuous casting process.

Aluminium Cold Rolling Mills. Typical cold rolling mill lines supplied by CNPT: u Cold breakdown rolling mills with 4Hi or 6Hi. u Cold finishing rolling mills. u 1+ 1 tandem cold rolling

Tandem cold rolling mill modeling for multivariable control synthesis. 17th IFAC Symposium on Control, Optimization and Automation in Mining, Mineral and Metal Processing, Aug 2016, Vienna, Austria. hal

TANDEM COLD ROLLING MILL Esteel Corp. TANDEM COLD ROLLING MILL Specification Contorl for rolling AGC or NC Photos ES ESteel amp; Used Machinery #187; Learn More. QT 2001 Construction of a Cold Rolling Mill Complex in the

COUPLED PICKLING LINE amp; TANDEM COLD MILL Highcapacity production of highquality products For a wide range of products, the required strip thickness, flatness and surface quality can be achieved more economically by linking the pickling and coldrolling processes.

Mills for cold reduction mill technology fullliners, who keeps the stateoftheartdesign competence with enhanced technology for the various mill Cold rolling mill type Typical mill stand types Production capacity (t/y)* Strip speed Type (m/min)* functions.

consultancy for tandem cold rollling mill Grinding.. (Min. Order).Hengxu tandem cold rolling mill for sale. US / Piece ( FOB Price). Tandem Cold Rolling Mill, Tandem Cold Rolling Mill Products. Read more

Rolling force is the most important technical parameter for the tandem cold mill. In this paper, the precise models and calculation process for the rolling force are introduced. The rolling force model is based on the BlandFord and Hill theory, and the roll flatten radius is calculated with the Hitchcoks formula. The deformation resistance of the strip is calculated with the model, whose

consultancy for tandem cold rollling mill. consultancy for tandem cold rollling mill Process models, advanced control support super steel mill Dec 13, 2010 The pickle line tandem cold mill (Get Price... Effect of Friction on Tandem Cold Rolling Mills Chattering. FullText Paper (PDF): Effect of Friction on Tandem Cold Rolling Mills Chattering...

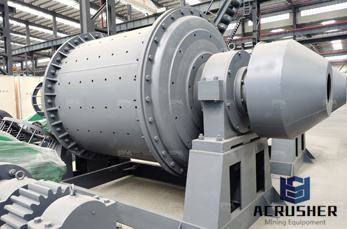

Consultancy For Tandem Cold Rollling Mill. Production capacity : /h . Feeding Size : 25mm . Discharging Size : Ball mill is also known as ball grinding mill. Ball mill is the key equipment for recrushing after the crushing of the materials. It is widely used in cement, Email: [email protected] Get Quote

Modern, efficient cold rolling mills can roll pickled sheets or strips at speeds of up to 4 m/s and tandem mills that are continuously working can produce up to million tons of cold rolled steel annually. The advantages of cold rolling.

Abstract: According to the chatter phenomenon of 3 rd stand of a steelworks sixroller tandem cold mill (TCM), vertical vibration of tandem cold mill was simplified to eight degrees of asymmetric freedom massspring system. Virtual prototype model on vertical vibration of tandem cold mill was established and natural frequencies and main vibration mode of mill were solved by using automatic

Tandem coldmill solutions from Primetals Technologies stand for high product yields combined with flexible production, low operational costs and simplified maintenance work. Depending on the product mix, the production capacity of continuous tandem mills from Primetals Technologies can exceed million tons per year.

WhatsApp)

WhatsApp)