Fused Silica or Quartz Glass Market Insights, Industry

2 #0183;#32;Press release Market Insights Reports Fused Silica or Quartz Glass Market Insights, Industry Outlook, Growing Trends and Demands 2020 to 2025 published on

WhatsApp)

WhatsApp)

2 #0183;#32;Press release Market Insights Reports Fused Silica or Quartz Glass Market Insights, Industry Outlook, Growing Trends and Demands 2020 to 2025 published on

Amorphous silicas as byproducts of industrial processes (silica fume) Amorphous silicas occur as a byproduct of industrial processes in flying ash and filter dust. When quartz is subjected to high temperatures (1500 #176;C to 2500 #176;C) during metallurgical or other production processes, grey to bluish fumes are produced.

fused silica industrial scale production; If you are trying to find where a material falls on the mohs scale . Get Price; Silica mineral Britannica . Silica mineral Silica mineral any of the forms of silicon dioxide (SiO2) including quartz tridymite cristobalite coesite stishovite lechatelierite and .

#0183;#32;This novel acid SiO 2 slurry is also environmentally friendly with significantly higher durability and stability, which is especially suitable for industrial scale production. Graphical abstract We simultaneously achieve an ultralow surface roughness of ~ nm and a high material removal rate of ~ m h 1 in the fused silica via a novel acid SiO 2 slurry.

Global Fused Silica Market 2020 research report starts with the essential presentation of Fused Silica market, basic descriptions, enduser applications, analyses and business chain formation.

Fused silica ceramics plays demanding role in high velocity missile/aircraft''radome development. Slip casting is the most common and commercially viable process utilized for radome production. Unfortunately slip casting cannot afford high density due to its poor green packing density which in turn results in poor rain erosion resistance.

Fused quartz or fused silica is glass consisting of silica in amorphous (noncrystalline) differs from traditional glasses in containing no other ingredients, which are typically added to glass to lower the melt temperature. Fused silica, therefore, has high working and melting temperatures. Although the terms fused quartz and fused silica are used interchangeably, the optical and

Heraeus has been producing quartz glass on an industrial scale with this process ever since. One Step Fused Silica Production. Chemical vapor deposition (CVD) For the production of optical fiber core rods, deposition of fused silica with a defined refractive index is done inside of fused silica tubes.

Fumed silica is synthesized by the pyrolysis method in which silicon tetrachloride reacts with oxygen in a flame, and the SiO 2 seed grows in size or aggregates [8].The solgel process [9,10] is performed in a liquid phase and silica nanoparticles are synthesized with an acidic or basic catalyst and alcoholic solvent in the presence of silicon alkoxide.

Minimum order quantity and would be ramping up to Volume quantities of: 200, 800, 1500, and 3000 wafers Question 2: 150mm (6quot;) Quartz wafers, DSP, 635um SEMI Notch, Serialized (or what other thicknesses available) (Single Crystal XCut) Looking for this in any or all of these materials Quartz, Fused quartz, Fused Silica We specifically are evaluating the Thermal Expansion and Fluorescence

#0183;#32;Industrial glass Industrial glass Glassmaking in the laboratory: Glassmaking requires a carefully weighed selection of raw materials. For laboratory melting, a batch is prepared from reagentgrade chemicals such as floated silica, sodium carbonate, calcium carbonate, alumina, and boraxall of which are assumed to convert to equivalent amounts of oxides after decomposition.

Two step fused silica production In this process, soot is deposited on a rotating bait rod (outside vapor deposition; OVD) or on the end of a rod that is pulled upwards (vapor axial deposition; VAD). The soot accumulates and forms a porous body with a density that is less than 25% of that of fused silica.

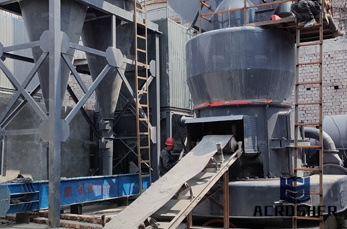

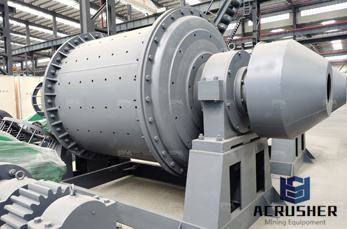

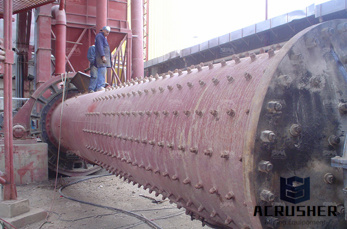

Fused Silica Industrial Scale Production. Fused Silica Industrial Scale Production Home limestone crusher in oman limestone crusher in oman we are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment.

WhatsApp)

WhatsApp)