(PDF) A comparison of wear rates of ball mill grinding

inspection of microstructure and They are used for grinding dry and wet materials in cement plants, lime factories, or metallurgical plants. process responses to model the ball mill

WhatsApp)

WhatsApp)

inspection of microstructure and They are used for grinding dry and wet materials in cement plants, lime factories, or metallurgical plants. process responses to model the ball mill

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotating about its axis. The axis of the shell may be either

Sourcing Guide for Cement Ball Mill: China manufacturing industries are full of strong and consistent exporters. We are here to bring together China factories that supply manufacturing systems and machinery that are used by processing industries including but not limited to: ball mill, grinding mill

18/7/2016#0183;#32;The audit of a closed circuit grinding system focuses on feed material characteristics, grinding progress in the mill, mill ventilation, classification and controls. Internal inspection of the mill can reveal a lot of important and vital information about the performance of the grinding system such as the separators behavior, influence of grinding media and the mill ventilation.

ball mill cement grinding inspection T23:11:40+00:00 BALL MILL MAINTENANCE The Cement Institute. The Ball Mill Maintenance course is designed to engage in the effective use of handson learning methodology as a unique combination of theory and practical work section applied to the maintenance inspection of the ball mill system.

This ball mill seminar is designed to train your personnel on the overall technology, operation and maintenance of your ball mill cement grinding system. The seminar focuses on the latest best practices for the operation and maintenance of ball mill systems to allow for optimal cement production, energy savings, reduced maintenance costs as well as the continuous improvement of the overall

LMATS Grinding Media Analysis Services Pre Shipment inspection. By using LMATS for grinding media pre shipment inspections to check that the Mill Grinding Balls are meeting the specification for hardness, shape, microstructure and chemical analysis the approval for shipping can be given.

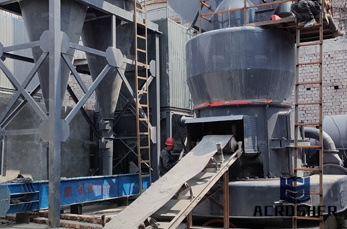

Roller Press with Ball Mill Cement Grinding Systems Selection Principle. As a professional contractor of cement plant, in the design process of cement plant, our team will select the most appropriate cement grinding system after fully considering the production condition and discussing with the client.

Ball mills and vertical roller mills are used for many grinding applications in cement production: raw meal grinding, coal and pet coke, and finish cement grinding. Improving the competences of the team plays a key role in the optimal utilisation of the grinding installation in your cement plant.

2/5/2019#0183;#32;What to expect from a cement ball mill inspection. Having an independent audit of your cement mill can identify opportunities for productivity improvements, including increasing production or lowering energy consumption. It is common to achieve a 510% gain in production by following mill audit recommendations.

What to expect from a cement ball mill inspection. Share. May 02, 2019. by GCP Applied Technologies GCP Applied Technologies draws upon a database of more than 400 audits of cement grinding systems conducted during the last 25 years for our clients. Such a mill audit requires mutually agreed upon targets and benefits and preaudit

A mio t/a cement plant is having a closed circuit ball mill for cement grinding: The mill has been operating with satisfactory performance interms of system availability and output, however power consumption was on higher side. System Description Mill Rated capacity 150 t/h OPC at

Cement ball mill is a kind of cement grinding equipment commonly used in cement plants. It is mainly used for grinding materials in cement clinker section. Cement ball mill is widely used in cement production, silicate products, new building materials, refractories, fertilizers, black and nonferrous metal mineral processing, glass, ceramics, and other industries.

FL provides sustainable productivity to the global mining and cement industries. We deliver marketleading engineering, equipment and service solutions that enable our customers to improve performance, drive down costs and reduce environmental impact.

Grinding Ball size range from 12125 mm, 4565 HRC, 123 % Cr. content; Grinding Cylpeb of required sizes 4565 HRC, 123 % Cr. content. The Grinding Media is produced by fullAuto casting lines, certified under international quality standards. We guarantee our Grinding Ball has low breakage rate, lower wear of consumption, and fast delivery terms.

Cleaning the machine after use: A ball mill must be cleaned after each operation or at the end of the working day. Major components like the grinding tool, grinding roller, and grinding ring are prone to wear. Because of that, each part or component should be regularly lubricated and checked for damage.

Cement quality, from the point of view of the ball mill grinding process, has no direct relationship with the pregrinding crushing and powder selection quality inspection index generally has two: cement screen residual value specific surface in recent years, the international cement quality inspection index is cement

WhatsApp)

WhatsApp)