Ball Mill: Operating principles, components, Uses

A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it

WhatsApp)

WhatsApp)

A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it

The minimal magnitude of ball size is calculated in millimeters from the equation: where is the maximum size of feed (mm); is compression strength (MPa); E is modulus of elasticity (MPa); b is density of material of balls (kg/m 3 ); D is inner diameter of the mill body (m).

Metallurgical ContentBall Mill Capacity VS Rod Mill CapacityWorking Principle amp; OperationRod Mill Capacity TableBall VS Rod Mill ConversionTypes of Mill DischargeBall Mill Trunnion and Mill Grate DischargePeripheral Grinding Mill DischargeLoad Capacity of Trunnion BearingsBall Mill amp; Rod Mill LinersGrinding Mill GearsGrinding Mill DrivesBall Mill Grinding CircuitBall Mill SpecificationsAll

Milling machine arbors are made in various lengths and in standard diameters of 7/8,1,1 1/4, and 1 1/2 inch. The shank is made to fit the taper hole in the spindle while the other end is threaded. NOTE: The threaded end may have left or righthanded threads. The milling machine spindle may be

Full slotting with an end mill is a demanding operation. The axial cutting depth should be generally reduced to around 70% of the edge length. Machine rigidity and chip evacuation should also be considered in determining the best method for the operation; End mills are

I prepared some compounds like perovskites using the planetary ball mill. Usually, I set the machine up to 300 rpm with 7 to 9 balls for different long times.

Ball mill Wikipedia

Mar 10, 2020#0183;#32;Materials such as iron ore, pain and ceramics are added to the ball mill. Next, the ball mill is activated so that it rotates either on its vertical or horizontal axis. As the ball bill rotates, the balls bounce around while striking the enclosed material.

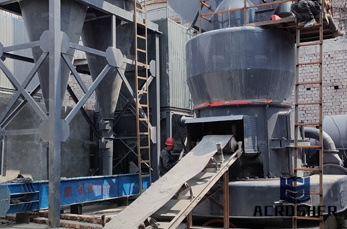

Ball mill is a key machine mainly used to process materials from crushing process, and it is widely used in various manufacture industries. It is widely used in Cement Plant, Clinker Grinding Unit, Quicklime Plant, Thermal Power Plant, Steel Mill, Mining etc.

Metallurgical ContentBall Mill Maintenance ManualOn Mill Installation and MaintenanceBall Mill Concrete FoundationsGrinding Mill FOUNDATIONGROUTINGBall Mill Sole Plate Am sure your Ball Mill is considered the finest possible grinding mill available. As such you will find it is designed and constructed according to heavy duty specifications. It is designed along sound engineering principles

Apr 07, 2011#0183;#32;Making the Ball Mill 1. Gather the necessary materials. Making a ball mill is a relatively simple process, but there are quite a few... 2. Make the base. The wooden base will serve as the support for the ball mill. It can be made by resting the wooden... 3. Mount the motor on the bottom of the

Put a little putty on the bolt first. Insert the bolt into the screwdriver''s bit holder. Cover the whole joint with putty. The more putty the better the ball mill stays together.

Make a Ball Mill in 5 Minutes Step 1: What You Need. A bolt, a nut and maybe a washer. Epoxy putty. Steel or lead balls which in my case I substituted... Step 2: Bolt the Container. Drill a hole dead center of the container''s bottom. Put the bolt through the hole. Thread... Step 3: Join the

WhatsApp)

WhatsApp)