BHP to ramp up Spence copper mine expansion

#0183;#32;BHP (ASX, LON, NYSE: BHP) plans to ramp up work at the ongoing billion expansion of its Spence copper mine in Chile, as measures taken to

WhatsApp)

WhatsApp)

#0183;#32;BHP (ASX, LON, NYSE: BHP) plans to ramp up work at the ongoing billion expansion of its Spence copper mine in Chile, as measures taken to

Heap leaching is an industrial mining process used to extract precious metals, copper, uranium, and other compounds from ore using a series of chemical reactions that absorb specific minerals and reseparate them after their division from other earth materials. Similar to in situ mining, heap leach mining differs in that it places ore on a liner, then adds the chemicals via drip systems to the ore, whereas in situ

Copper Mining and Production Processes Explained

Another example relating to treatment of intrusion water from a copper mine is shown below. This example shows the reduction of contaminants from dam water entering the mines water treatment plant. The water was first treated by MFRO and the concentrate was subsequently treated by a Disc TubeTM RO system with the following results:

management of mining, quarrying and oreprocessing waste in the European Union. to establish treatment objectives according to required future land use (for example, laws, cannot be endless. Even where the facility becomes a permanent structure, it is

Ore Treatment. COPR was used as fill in preparation for building foundations, construction of tank berms, roadway construction, filling of wetlands, sewerline construction, and other construction and development projects. From: Environmental Forensics, 1964. Related terms: Energy Engineering; Environmental Impact; Smelting; Uranium; Life Cycle Assessment

HighGrade Gold and Copper on the Pathway to Production with Dor#233; Copper Mining CEO Ernest Mast December 2, 2020 Highestgrade undeveloped copper and gold deposits in North America. In this interview, Dor#233; Copper Minings president and CEO Ernest Mast provides an overview of the companys investment value proposition, describes why the company is undervalued and explains the plans

The process used to treat sulfide copper ores begins at the mine site, where the copperbearing minerals are physically separated from the rest of the rock. The flow diagram below shows how the percentage of copper increases as the ore is refined, first

Mining for Copper Bearing Ore. There are two categories of copper ore; sulphide ore which is processed to enrich it before smelting, and oxide ore that is subjected to acid treatment. The major producers of copper ore are Chile, USA and Australia, the vast majority of the ore coming from open pit mining. In open pit mining the layers of soil

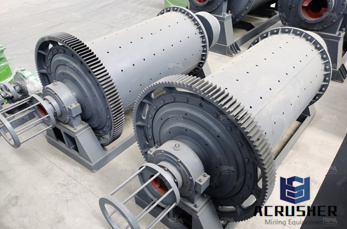

MOLYBDENUM PLANT NEWS Sister Facility for Copper Tailings Treatment Plant CHILE The June 23, 2004 by Canadian Mining Journal Editor Companies. Amerigo Phase 2 is being planned to raise production to 20,000 tonnes/year of copper by adding additional grinding capacity of the coarse fraction at a capital cost of US million.

Processes: copper mining and production. Copper is found in natural ore deposits around the world. This page explains copper mining: the production route taken from orecontaining rock to a final product that is the highestpurity commercial metal in existence and used in a wide variety of applications essential to modern living.

Ore Treatment. COPR was used as fill in preparation for building Mining and mineral processing have significantly contributed to the advancement of human civilization and Detailed production data for the year 2010 has been used to populate the inventory model for the copper ore extraction, and both the copper oxide and sulphides ore

#0183;#32;After mining copper metal, copper ore concentrate levels are typically between 24 and 40 percent. I found no reference here to the potential costs of waste treatment or indemnification,

#0183;#32;Ore treatment and sales at Palabora. Palabora employs one of the most complex recovery circuits installed at any copper mine, producing eight metal, mineral and chemical products in 20 different varieties and grades. The complex includes a concentrator, copper smelter and refinery, currently capable of producing 135,000tpa of copper plus

A KS4 education resource covering copper mining, extraction and pyro processing. Information on processes for extracting copper. The crushed ore rests on a leakproof membrane to protect the underlying ground and prevent the acid and copper ions polluting the local water table The solvent extraction phase of treatment occurs in two stages.

WhatsApp)

WhatsApp)