Process Plant Design Considerations for High Silver Gold

Process Plant Design Considerations for High Silver Gold Ores Published on March 2, 2016 March 2, 2016 54 Likes 6 Comments

WhatsApp)

WhatsApp)

Process Plant Design Considerations for High Silver Gold Ores Published on March 2, 2016 March 2, 2016 54 Likes 6 Comments

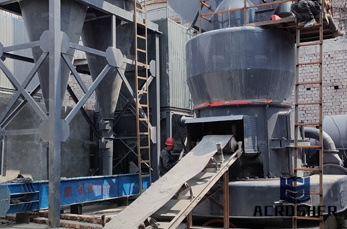

Copper Ore/gold/chrome Ore Processing Plant, Find Complete Details about Copper Ore/gold/chrome Ore Processing Plant,Copper Ore Processing Plant,Gold Mining Plant,Chrome Ore Concentrate Plant from Supplier or ManufacturerHenan Xingyang Mining Machinery Manufactory

#0183;#32;Gold processing Gold processing Mining and concentrating: The nature of the ore deposit determines the mining and mineral processing techniques applied. Oxide ore deposits are frequently of such low grade (, 3 to 10 parts per million) that extensive mineral processing cannot economically be justified. In this case they are merely shattered by explosives and then piled into

Applied Materials: Iron ore, copper ore, gold ore, river gravel, limestone, granite, basalt, diabase, andesite, etc. Beforesale Service Provide you the purchase plan, process flow design and manufacturer equipment according to your special demands

concentrations of these base metals are very low, they have a negative impact on the downstream operations. In order to obtain the required throughput of the plant during the mill stage, more steel balls are added. The steel consumption is 1 kg per ton of ore. This causes the iron content to increase in the

As a matter of fact, a SART plant can reduce the operational cost and increase the incomes in a gold mine, although the main achievement is to make feasible the treatment of a goldcopper ore deposit.

Gold CIL (Carbon in Leach) Process is an efficient design of extracting and recovering gold from its ore. By cyaniding and carbon leaching crushed gold ore slurry simultaneously, CIL process lower the gold mining operation cost and increase gold recovery rate to a degree of 99%.

High Capacity Gravity Concentration Plant For Copper,Chrome,Iron Ore, Find Complete Details about High Capacity Gravity Concentration Plant For Copper,Chrome,Iron Ore,Gravity Concentration Plant,Chrome Ore Washing Plant,Cheap Price Gold Mining from Mineral Separator Supplier or ManufacturerZhengzhou Yufeng Heavy Machinery Co., Ltd.

The four major steps in the production of marketable copper are mining, concentrating, smelting, and refining. In a few instances, however, leaching takes the place of concentrating, smelting, and refining. At present, although considerable leaching and directsmelting ores are produced, the bulk of the copper ore mined is concentrated. The milling of copper ores as practiced in the larger

Northern Chrome Producers has seen a 6% increase of additional yield in plant recoveries since they retrofitted Multotecs HX3 and HX5 mineral spiral concentrators in February 2015. Each of these mineral spiral concentrators, part of Multotecs gravity concentration equipment within its range of mineral processing equipment, have feed tonnage capacities ranging from 4 9 tons per hour

Complete Concentration Processing Plant for Chrome/Copper/Gold Ore 200 ton per day Chrome Iron ore beneficiation concentrate plant Get Price advances in magnetic separation of ores 911 Metallurgist Magnetic separation of iron ores is one of the fastest growing segments of tion in the field of ore beneficiation It is a sim ple yet effective method used for some ing phosphate .

#0183;#32;As expected, the copper in the circuit reduced to a low level, but when sulfide coppergold ore processing resumed, the copper concentration in the leach circuit did not attain previous levels even though a higher copper orebody was being mined. The copper recovery plant was operated intermittently for a few months and was eventually shut down.

Gold ore . Prominer maintains a team of senior gold processing engineers with expertise and global experience. These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc., to achieve the processing plant of optimal and costefficient process designs.

WhatsApp)

WhatsApp)