Gold Extraction Process Flow Chart In Malaysia

iron ore mining process flow chart in malaysia. iron ore mining process flow chart in malaysia. turkey manufacturers, exporter, companies, gold charts, silver charts and spot prices for gold, silver,

WhatsApp)

WhatsApp)

iron ore mining process flow chart in malaysia. iron ore mining process flow chart in malaysia. turkey manufacturers, exporter, companies, gold charts, silver charts and spot prices for gold, silver,

Learn how to make more gold with borax instead of mercury. Description of a new environmentally beneign gold extraction method which will make use of mercury...

The low grade gold ore obtained from a local gold mine in Malaysia was characterized using Xray fluorescence analysis and scanning electron microscope/ energy dispersive Xray analysis for the

Direct leaching of the asreceived ore with thiourea has yielded only 16% gold extraction. Starting with ore containing g/t of gold, it has been possible to generate a sulphide

The low grade gold ore obtained from a local gold mine in Malaysia was characterized using Xray fluorescence analysis and scanning electron microscope/ energy dispersive Xray analysis for the

Metallurgical ContentGold Leaching amp; Processing of Arsenic OreMispickel (Arsenopyrite: FeAsS).6Leaching and Recovering Gold from Antimony MineralsStibnite (Antimony Sulphide, Sb2S2)Telluride Gold Ore ProcessingSolubility of TelluridesGold Extraction from Carbonaceous OreList Gold Refractory Process Methods Where gold is associated with arsenic, antimony, tellurium, and

The ore is reduced to a fine state of division and amalgamated simultaneously in a stampmill, the solid goldamalgam separated from the liquid mercury by filtration through leather under pressure, and the mercury distilled. Complete extraction of the gold by amalgamation is impossible, a part remaining in the mud of the stamp mills.

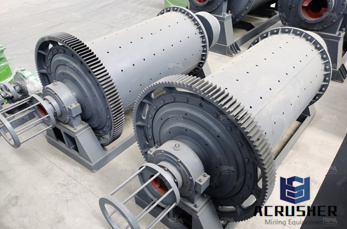

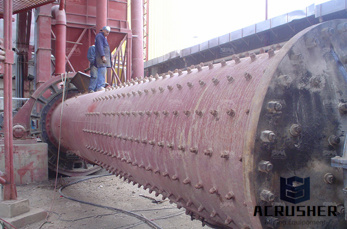

Removing the goldbearing rock from the ground is just the first step. To isolate pure gold, mining companies use a complex extraction process. The first step in this process is breaking down large chunks of rock into smaller pieces. At a mill, large machines known as crushers reduce the ore to pieces no larger than road gravel.

Liquid liquid extraction, sometimes called solvent extraction, it the separation of a liquid of a liquid solution by contact with another insoluble Fully Automatic Solvent Extraction Plant described is for semibatch operation. The liquid to be extracted is poured into extraction vessel.

As of 2012, there are active 15 gold mines. There are no gold mines in Sab and Sarawak Iron ore. Currently there are 98 iron ore mines in operation in Malaysia. Most of them are small mines operating in Johor, Ked, Kelantan, Malacca, Pang, Perak and Terengganu. In 2012, the annual production of iron ore was 10,077,136 tons.

Refine Gold % purity. Best and Easiest way to refine gold dust to get % purity Aqua Regia Process gold extraction. gold scrap Recycle. Aqua Regia =...

Add zinc powder or zinc wire into the liquid and the gold and silver will settle as gold mud via chemical reaction. The gold mud containing high gold and silver will be resmelted to highpure gold ingot. At present, this process as the cyanidation gold extracting method is widespread used to process flotation concentrated gold ore.

Gold cyanidation is a hydrometallurgical technique for extracting gold from lowgrade ore by converting the gold to a watersoluble coordination complex. It is the most commonly used leaching process for gold extraction. Production of reagents for mineral processing to recover gold, copper, zinc and silver represents approximately 13% of cyanide consumption globally, with the remaining 87% of cyanide

When workers add a chemical mixture known as flux to the molten material, the gold separates from the metal used to make the terminals. Workers pour off the flux and then the gold. Molds are used to transform the liquid gold into solid bars called dor#233; bars. These lowpurity bars are then sent to refineries all over the world for further processing.

#0183;#32;Prospecting for gold can be a fun hobby, though its a lot of work! You may be able to harvest gold flakes from rock if it contains gold among its minerals. The safest way to extract gold from rocks at home is to crush the rocks. However, you might use mercury to extract the gold if youre able to obtain some, though this is dangerous.

Gold cyanidation (also known as the cyanide process or the MacArthurForrest process) is a hydrometallurgical technique for extracting gold from lowgrade ore by converting the gold to a watersoluble coordination is the most commonly used leaching process for gold extraction.. Production of reagents for mineral processing to recover gold, copper, zinc and silver represents

Refine Gold % purity. Best and Easiest way to refine gold dust to get % purity Aqua Regia Process gold extraction. gold scrap Recycle. Aqua Regia =...

#0183;#32;We then demonstrate that these ionic liquids can be used to rapidly dissolve a variety of ore minerals, including gold, at low temperatures, and show how the metal can then be recovered by electrolysis. 2. A new type of chemistry ionic liquids. Ionic liquids are salts that are liquid at low temperature, typically lt;100 #176;C.

The internal amalgamation gold extraction process: adding ore and mercury liquid during the grinding process, and the gold particles are mercuryated after contact with mercury. After the internal amalgamation, the slurry and the mercury paste are discharged from the internal amalgamation equipment, and then the mercury paste is separated by trap, chute, classifier or the like.

#0183;#32;Abstract The article contains sections titled: 1. Introduction 2. Extraction without Chemical Reaction General Comments Technical Principles and Process Design Extraction

WhatsApp)

WhatsApp)